gravionBreak free from outdated limits

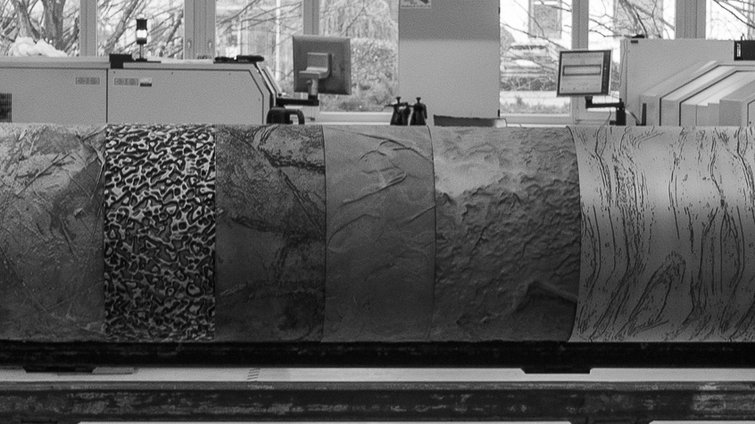

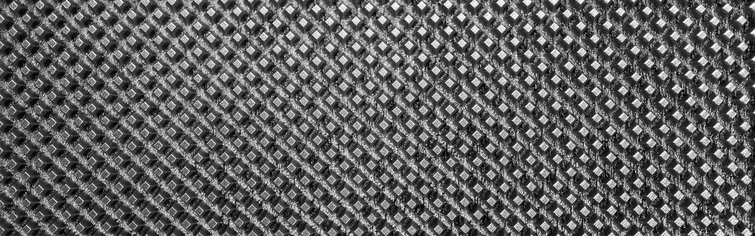

Choose from wood, linen, leather, line, pyramid, honeycomb, worm, or sand textures — or let us craft your custom pattern with your logo. For the tissue industry, we master all embossing types: overall, border, punta/punta, single, double, and triple height. We even provide A4 sheet samples to help you visualize your results before production. Plus, our 3D visualizations let you preview exactly how your embossed material will look, giving you the freedom to explore and refine designs before the first roller is made.

Design & DevelopmentFrom Idea to Innovation — We Co-Create

Our simulation tools let you preview embossing results before production, minimizing risks and accelerating time-to-market.

Together with our 3D specialists and surface designers, we transform raw ideas into refined and manufacturable concepts — visually compelling, technically feasible and ready for real production.

Every surface is developed with intention: crafted aesthetics that elevate products, reinforce brand identity and shape how the world experiences touch.

This is where imagination becomes clarity — and innovation begins to take form.

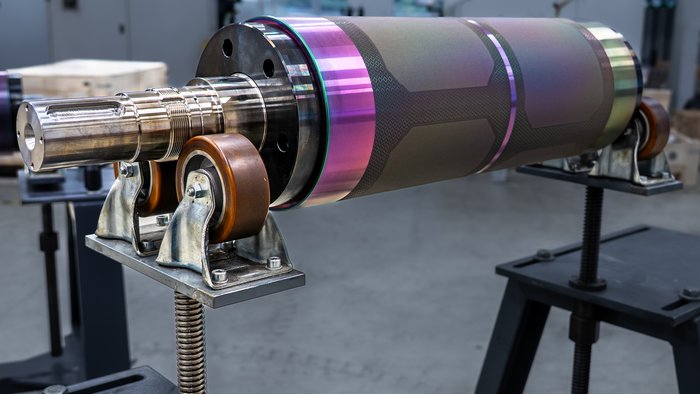

FinishingProtect what performs

Our high-performance coatings are engineered to maximise durability, protect surface brilliance and guarantee long-term stability in production. From wear resistance to anti-adhesive properties and hygiene-sensitive applications, every coating is tailored to your process and material. By reducing buildup, simplifying cleaning and extending roller lifespan, we ensure uninterrupted quality and predictable performance.

Our portfolio ranges from hardchrome to premium multi-layer coatings, fine-tuned for industrial reality — not theory.

QualityBreak with convention

During the years he spent working in the embossing industry, Dietmar Buchholz saw the disadvantages of conventional methods first-hand:

They are too slow, too imprecise and too harmful for both people and the environment.

After lots of work developing, refining and investing in his ideas, he had a breakthrough: Nowadays, gravion uses no acid at all in its manufacturing process, using clean laser technology even for the toughest materials. The embossing results this achieves are significantly more consistent, which means they can be stacked and reproduced more successfully.

- Consistent Results: Laser precision for flawless embossing every time.

- Safe & Clean: Acid-free process, eco-friendly and reliable.

SustainabilityImproving Efficiency

One thing is crystal clear to the company's founder: "Our resources are finite and will not become cheaper in the long term.

As a result, at gravion we scrutinize existing technology and spend every day developing more efficient solutions."

For instance, the gravion team has reduced the amount of waste produced by the manufacturing process by such an extent that a regular trash will hold it all. The power that gravion uses comes from renewable sources of energy. The roof of the company's premises is used to generate power and even rainwater is collected, treated and re-used.

Dietmar Buchholz and his team put everything they've got into acting in line with the company's motto: Be different – be innovative!

Another of gravions strengthsExtend Roller Llifetime. Reduce Costs.

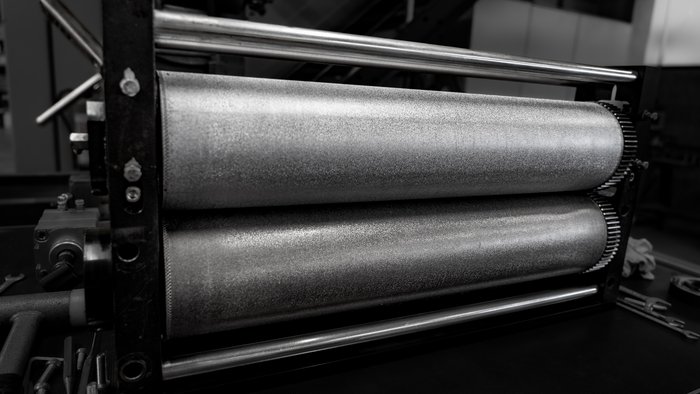

Our reconditioning program restores and optimizes rollers, maximizing performance, minimizing downtime, and ensuring every investment delivers lasting value.

Tailored refinements and surface enhancements make each roller perform perfectly for your specific materials and processes.

gravionSix Key Benefits

Apply, engrave, emboss, or finish with precision. Our rollers empower businesses across industries and materials to achieve outstanding results.