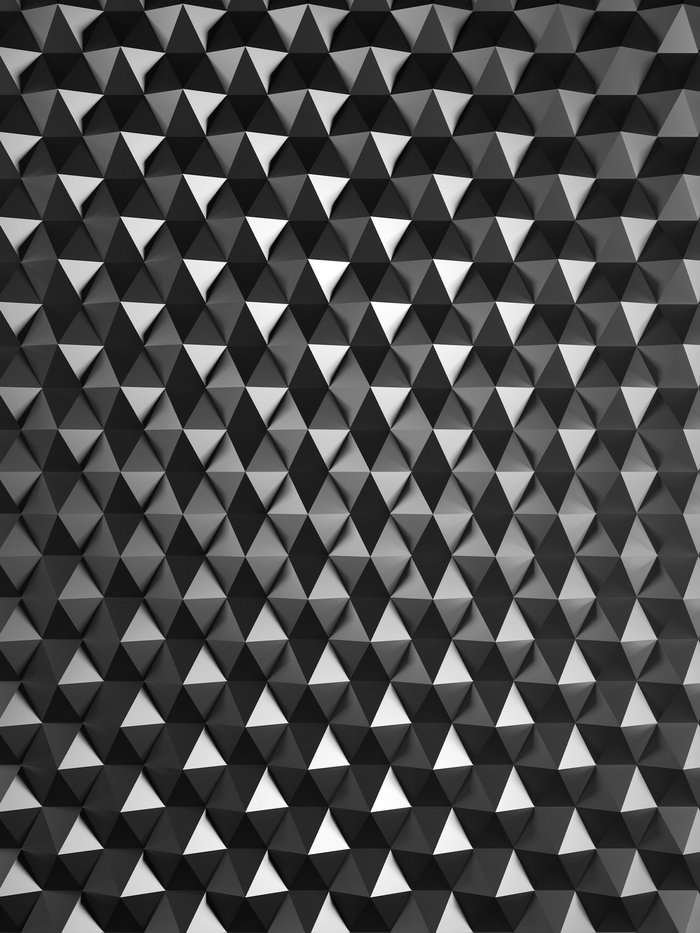

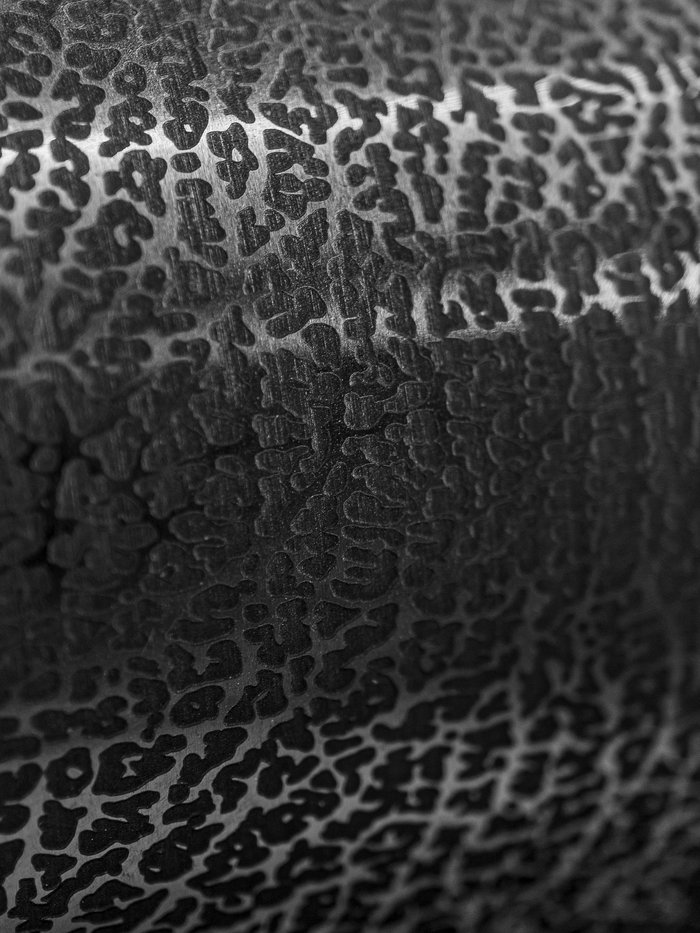

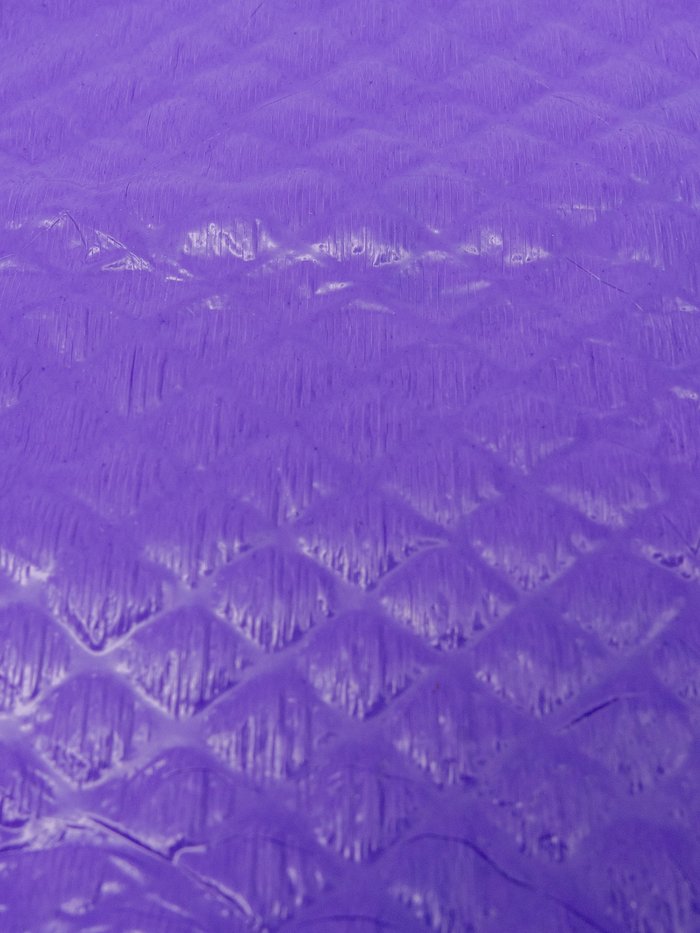

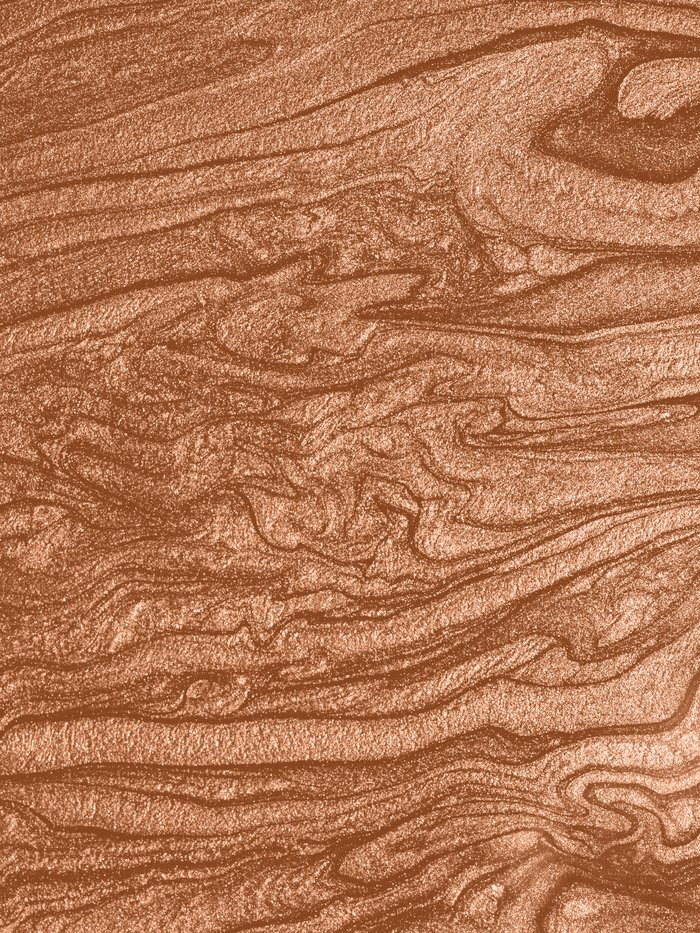

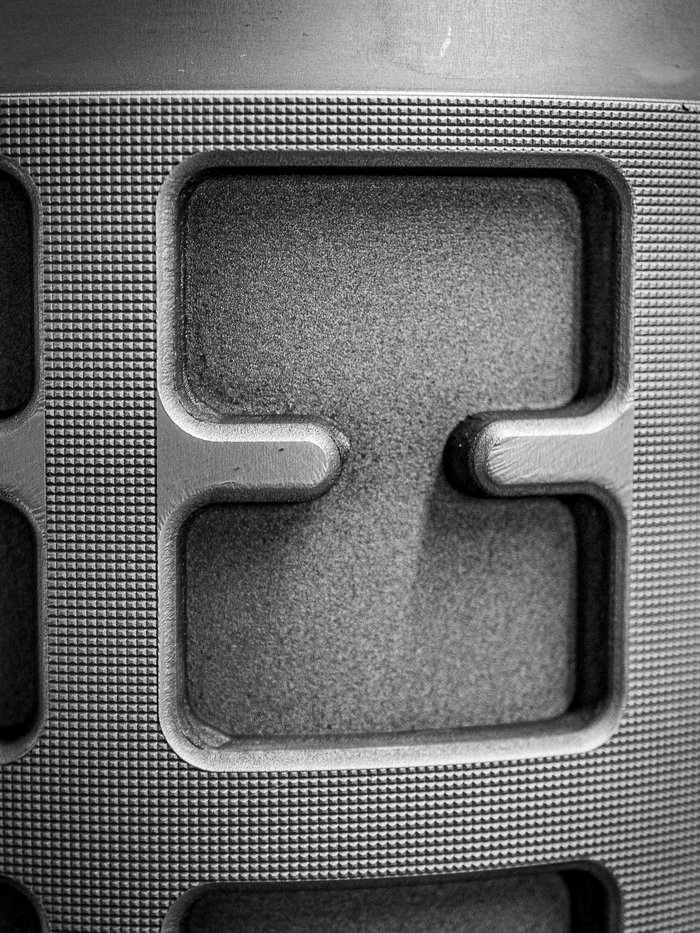

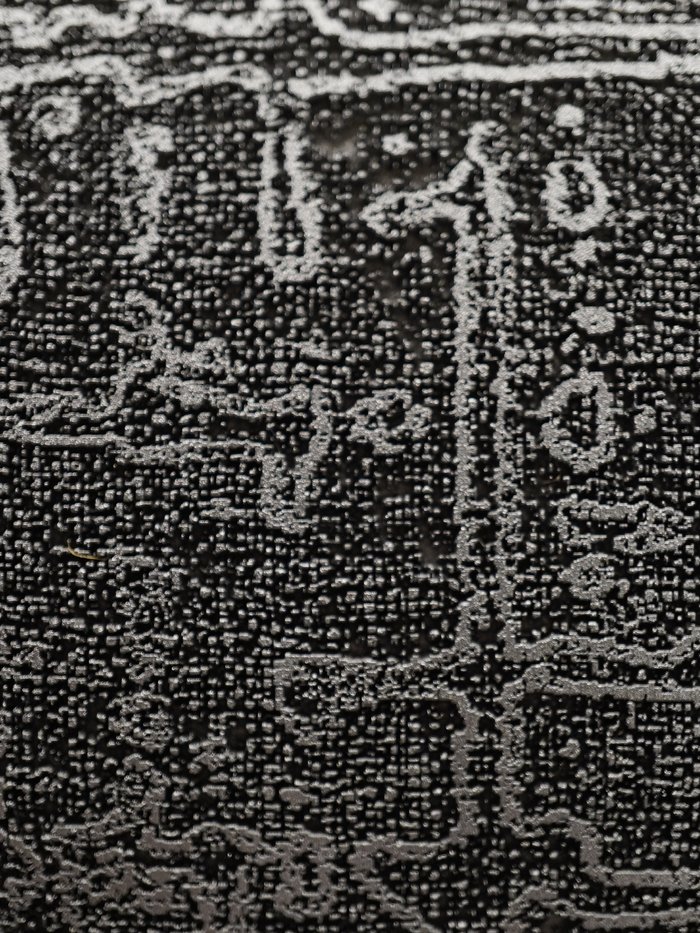

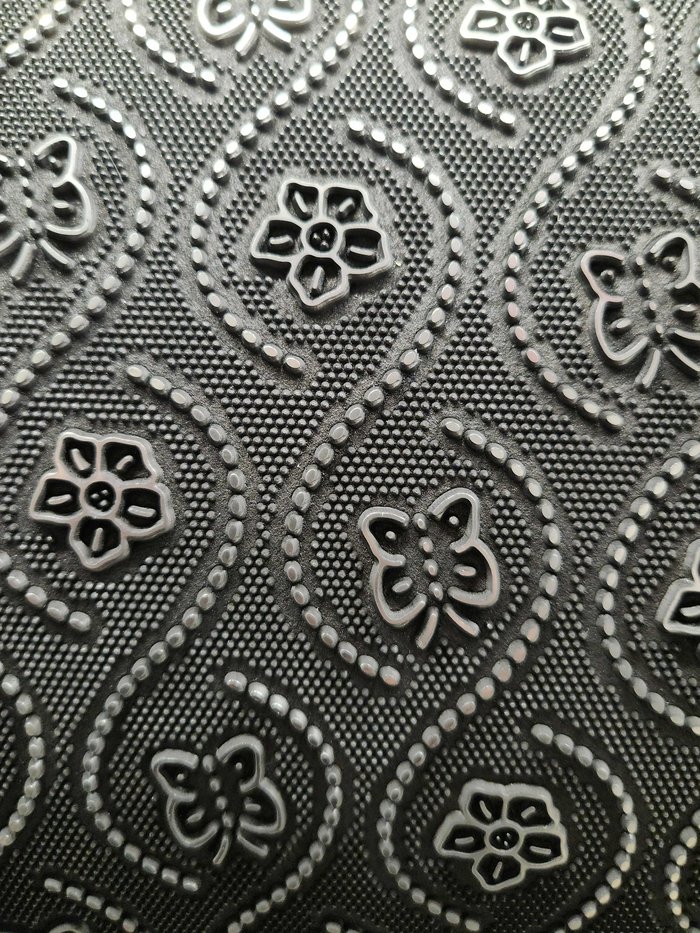

Design & Development

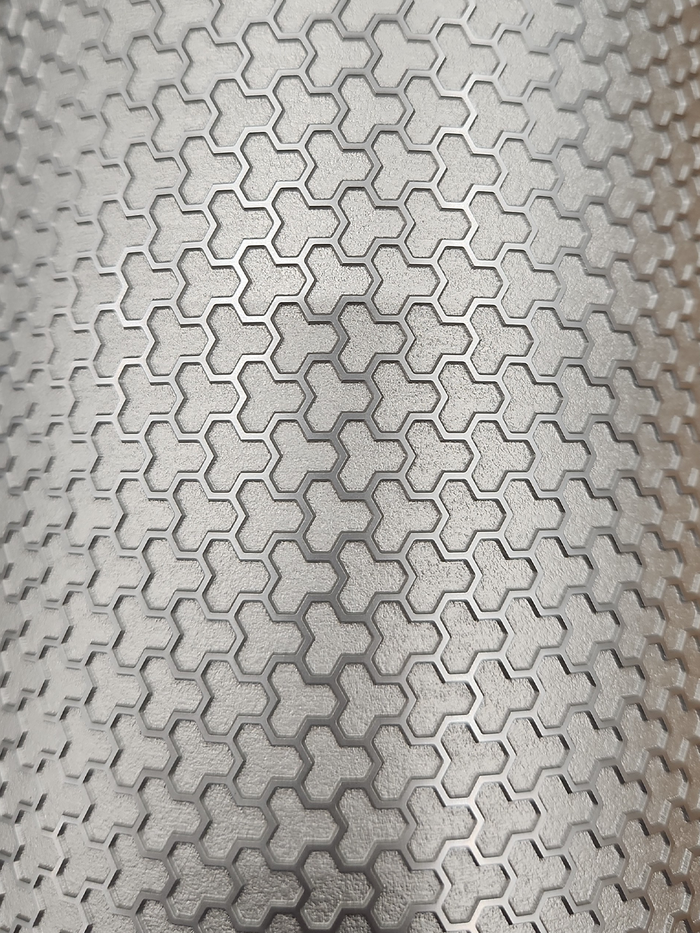

Innovation begins long before the engraving starts. At Gravion, design and development form the beating heart of our process. We act as your creative and technical sparring partner, transforming ideas into engineered perfection. Using 3D modeling, texture simulation, and iterative prototyping, we refine every pattern for maximum embossing performance and optimal material flow.