“History doesn’t repeat — it engraves.”

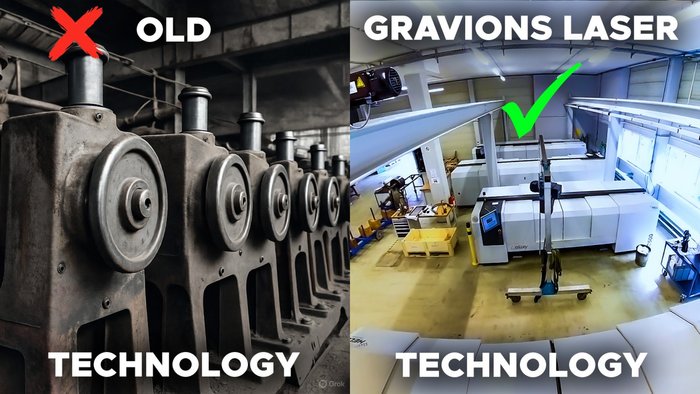

If you're still relying on acid etching for your embossing rollers, this is your urgent wake-up call. Across industries like tissue, packaging, décor, nonwoven, leather, film, and beyond - any sector that depends on high-precision embossing rollers - you're standing on the edge of a cliff. Acid etching isn't just outdated; it's a ticking time bomb of environmental hazards, health risks, skyrocketing costs, and tightening regulations that could bankrupt your operations overnight. Just like Kodak buried its own digital future, clinging to chemical processes that once seemed invincible, you're risking the same fate.

This in-depth blog post isn't just a story - it's a siren. We'll expose the hidden dangers of acid etching in brutal detail, map out why your embossing needs are under siege, and guide you through a clear, step-by-step funnel to switch to gravion's revolutionary laser technology. By the end, you'll see the path from awareness of the crisis to decisive action: transforming your production into something faster, cleaner, and future-proof. The clock is ticking - will you heed the warning?

The Acid Etching Trap: Why It's Poisoning Your Business and the Planet

Acid etching has been a staple for decades in creating embossing rollers—dipping steel bases into corrosive baths of nitric, hydrochloric, or hydrofluoric acids to etch intricate patterns. It seemed efficient once: cost-effective for complex designs, scalable for high-volume runs in tissue for softness patterns or packaging for branded textures. But today? It's a relic that's actively harming your bottom line and legacy.

Let's break down the dangers—no sugarcoating:

- Environmental Devastation: Acid etching generates toxic waste—corrosive sludge laden with heavy metals and chemicals that leach into soil and waterways if not disposed of perfectly. Improper handling leads to widespread contamination, emitting CO2 and other greenhouse gases during chemical production and neutralization. In an era of global sustainability mandates, your operations could face fines or shutdowns as regulations like the EU's REACH or U.S. EPA standards clamp down harder.

- Health Hazards to Your Team: Fumes from hydrochloric or hydrofluoric acids cause severe respiratory damage, skin burns, and eye injuries—risks that escalate with prolonged exposure in etching facilities. Workers need hazmat gear, ventilation systems, and constant training, driving up insurance and liability costs. One accident could cost millions—and irreparable damage to your company's reputation.

- Operational Nightmares: Etching is slow (days for deep patterns), inconsistent (variations in acid concentration lead to defects), and wasteful (over-etching requires rework). As raw material prices soar and supply chains falter, these inefficiencies compound: Higher energy use, more scrap metal, and escalating disposal fees. For embossing roller users in leather (for luxury textures) or nonwoven (for medical fabrics), even minor inconsistencies mean rejected batches and lost contracts.

The stats are damning: As awareness grows, regulations are tightening, and costs are rising - making acid etching not just risky, but unsustainable. If you're in tissue production, where patterns must be ultra-fine for consumer appeal, or packaging, demanding rapid design iterations for seasonal branding - one etching mishap could sideline your entire line. This is your Kodak moment: Ignore it, and history will engrave your downfall.

The Broader Crisis: How Outdated Etching Is Crippling Embossing-Dependent Industries

Your industry isn't isolated - it's interconnected. From tissue giants embossing quilted patterns for softness, to packaging firms creating tactile anti-counterfeit features, to décor producers texturing foils for woodgrain effects - every embossing roller user faces the same etching pitfalls. Mechanical and chemical methods dominate 70% of the market still, but demand for digital alternatives surges 15–20% yearly as consumers prioritize eco-friendly, customizable products.

Consider the ripple effects:

- In Tissue and Nonwoven: Etching's environmental footprint clashes with hygiene standards and green certifications. Delays in roller production mean missed market windows for trend-driven designs, like sustainable bamboo textures.

- Packaging and Film: Volatile supply chains amplify etching's waste—corrosive byproducts add to plastic pollution narratives, alienating eco-conscious brands.

- Leather and Décor: High-end personalization (e.g., monogrammed bags) suffers from etching's imprecision, leading to costly reworks and slower time-to-market.

The pandemic exposed these cracks: Shorter timelines, personalized demands, and sustainability pressures made etching a bottleneck. Clinging to it isn't loyalty to tradition -it's self-sabotage. As competitors pivot, your margins erode, talent flees hazardous jobs, and regulators circle. The question isn't if your embossing process will break - it's when.

Visualize the trap: A polished steel disk reflecting a dissolving Kodak film strip, now overlaid with acid-dripping rollers rusting away. History doesn't forgive hesitation.

Escaping the Trap: Your Step-by-Step Funnel to gravion's Revolutionary Laser Technology

"From Kodak’s fall to gravion’s rise: a warning for etching users."Here's the good news: There's a proven escape route. gravion's laser technology isn't a tweak - it's a total reinvention, laser-engraving up to 1 mm deep directly into solid steel with sub-millimeter precision. No acids, no fumes, no waste - just clean, repeatable excellence. Patented exclusively by gravion, this process transfers innovations from steel plate lasering to embossing rollers, slashing production times while boosting durability.

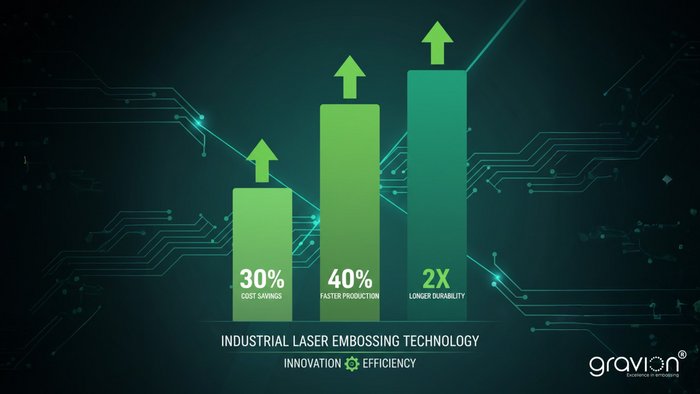

But switching isn't a leap - it's a guided funnel. We'll walk you through it: From recognizing the pain (you're here) to full implementation. Each step builds desire, proving why gravion's laser tech delivers 5x efficiency gains, resource savings, and a slashed CO2 footprint compared to etching.

Step 1: Awareness – Acknowledge the Shift (Spot the Signs in Your Operations)

Start by auditing your current setup. Are etching delays costing you 20-30% in downtime? Is waste disposal eating 10-15% of your budget? gravion's laser tech eliminates these: It's a non-contact process using only electricity, producing zero hazardous byproducts and minimal scrap—ideal for regulated industries like tissue and packaging. Early adopters report immediate relief from compliance headaches.

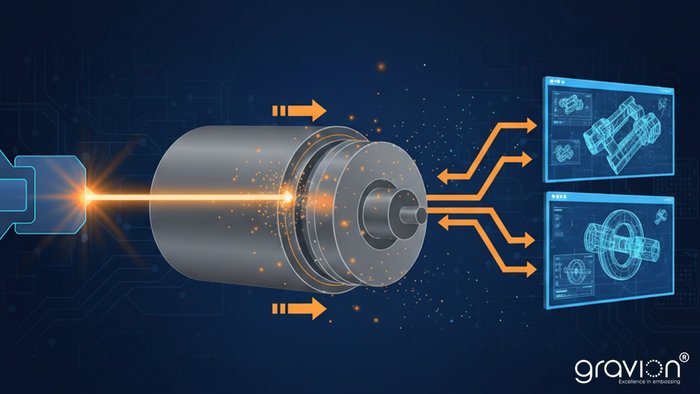

Step 2: Interest – Dive into the Details (How gravion's Laser Works for Your Rollers)

gravion's system begins with digital design upload - your CAD files translate instantly to laser paths. A high-powered fiber laser vaporizes material layer by layer, achieving depths up to 1 mm in solid steel without masks or chemicals. For embossing, this means flawless, repeatable patterns: Quilted tissue motifs with micron-level accuracy, or leather textures that endure 50% longer than etched versions.

Key specs:

- Speed: Up to 10x faster than etching—new rollers in hours, not days.

- Precision: Sub-millimeter resolution for complex 3D effects, reducing defects by 90%.

- Sustainability: 5x less energy, no toxins—aligning with ESG goals and cutting disposal costs by 80%.

- Versatility: Scales for any material or industry, from nonwoven medical fabrics to décor films.

In Rheinfelden, Germany, and our U.S. facility, we handle full lifecycle: Design consultation, prototyping, production, and refurbishment. No more etching's variability - every roller is identical, every run consistent.

Step 3: Desire – See the Proof (Real Wins and Your ROI)

Imagine global producers cutting tissue embossing costs by 30% with laser rollers that adapt designs within minutes — or leading packaging manufacturers accelerating their prototype cycles to stay ahead of the market. Premium leather brands now personalize embossed surfaces in days, increasing margins by up to 25%. Across all industries, gravion clients report: 40% faster time-to-market, 50% less maintenance, and full regulatory compliance — turning sustainability into a powerful selling point.

Your ROI? Calculate it: compare the hidden costs of etching — waste, health risks, production delays — with laser’s upfront efficiency. Most partners see payback in just 6–12 months, with rollers lasting twice as long under high-pressure embossing.

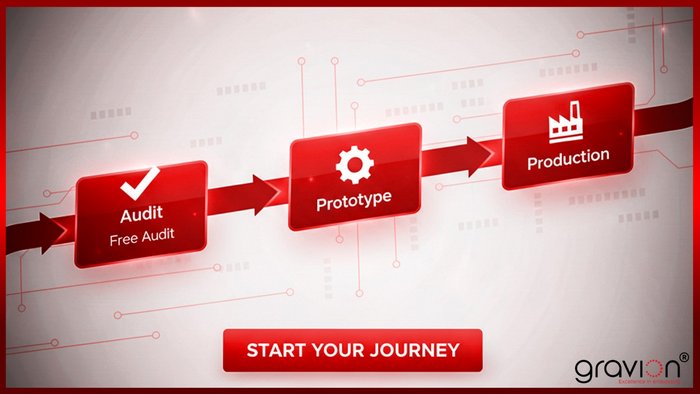

Step 4: Action – Make the Switch (Your Seamless Transition to gravion)

Ready? Contact us for a free audit: We'll analyze your current rollers, simulate laser upgrades, and prototype a sample at no risk. From there: Custom production in weeks, installation support, and ongoing optimization. Our limited capacity means acting now secures your spot—don't let waitlists grow.

This funnel isn't theory- it's your blueprint to leadership. gravion's laser tech isn't just better; it's essential for the future.

The Imperative Now: Forge Ahead or Fade Away

Before a horizon of blinding light rises a gravion roller - its laser-engraved patterns glowing as pathways to infinity. Powered by clean, revolutionary tech, this is the unbreakable future: Precise, rapid, sustainable. Industries thriving in the next decade will ditch etching's poisons for laser's promise -choosing innovation over inertia. History has etched this tale before; gravion equips you to rewrite it.

Will you lead the revolution—or etch your own obsolescence?

Demand surges; slots fill fast. Call +49 7623 74 790-00 or email info@gravion.eu today for your free transition audit.

Let's laser your future into steel - starting now. gravion is proud to be recognized as a Top 100 Innovator 2025.